more

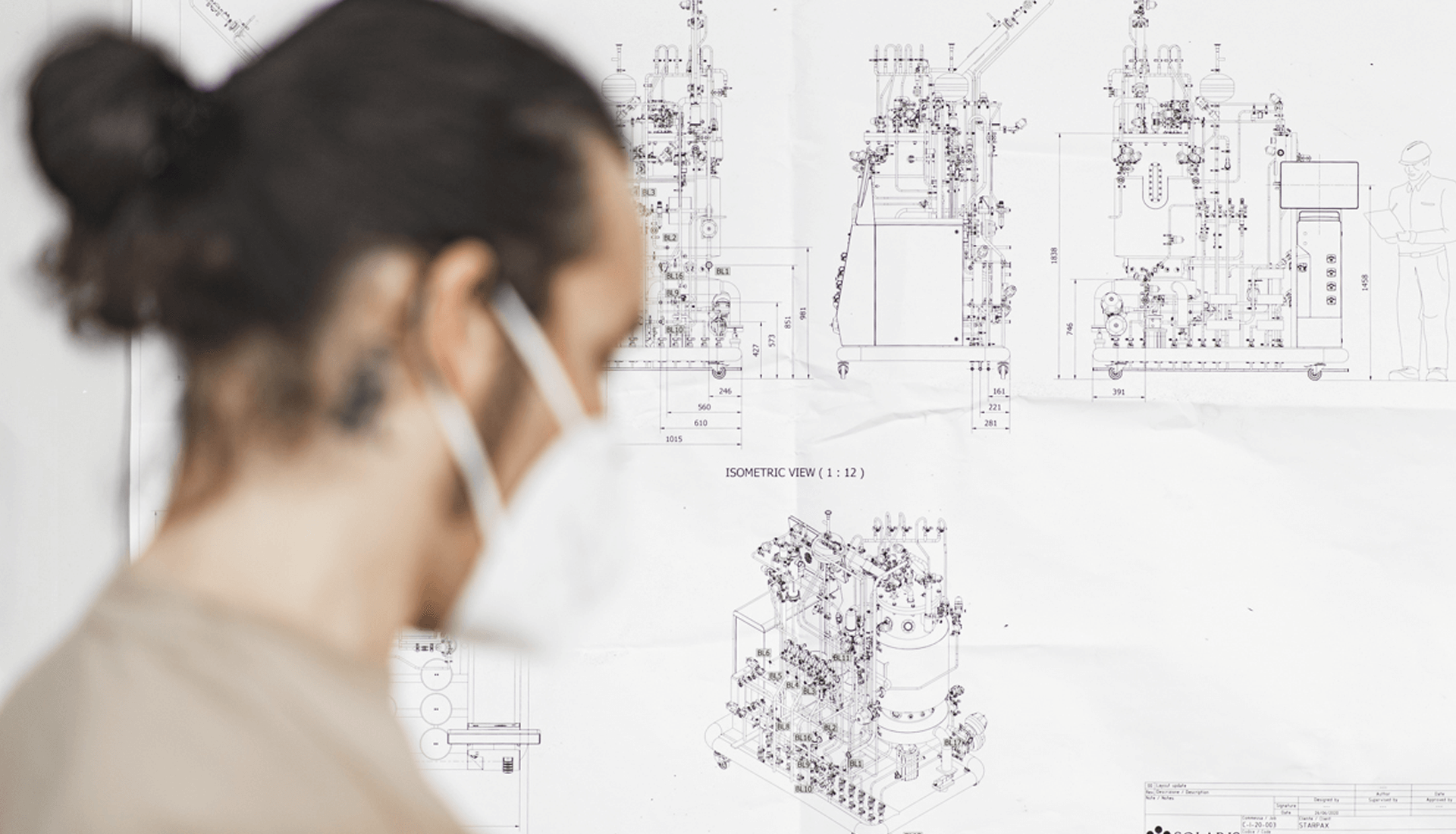

Design of fermenters, bioreactors and filtration systems

Basic Engineering

Solaris can support all clients who already have the know-how with the design of a basic engineering, a basis of detailed design and engineering development for the construction of a whole process plant.

The basic engineering design includes

Frequently Asked Questions

Bioreactors engineering: definition and design of all engineering parameters (e.g. internal and external mass transfer, fluid velocity, shear stress, electrical current distribution, etc) preliminary to the bioreactor manufacturing:

- bioreactor design characteristics and monitoring & control system

- bioreactor design: size, dimensioning

- bioreactor instrumentation

Designing the optimal engineering parameters is crucial not only to reduce the cost and time of experiments, but also to enhance efficacy and functionality of the bioreactor.

Biotechnology engineers design process equipment (fermenters, bioreactors, process tanks) aimed at producing biomass to be used as raw material for the creation of products to be used in several fields of application (Food & Beverage, Agriculture, Pharma, etc. among many). They create all the related technical documentation, such as Piping and Instrumentation Diagrams (P&Id), layouts, instrumentation lists, fluids lists, nozzle lists, etc. just to mention a few.