Pilot and Industrial Tangential

Flow Filtration Systems

Solaris Filtration Systems

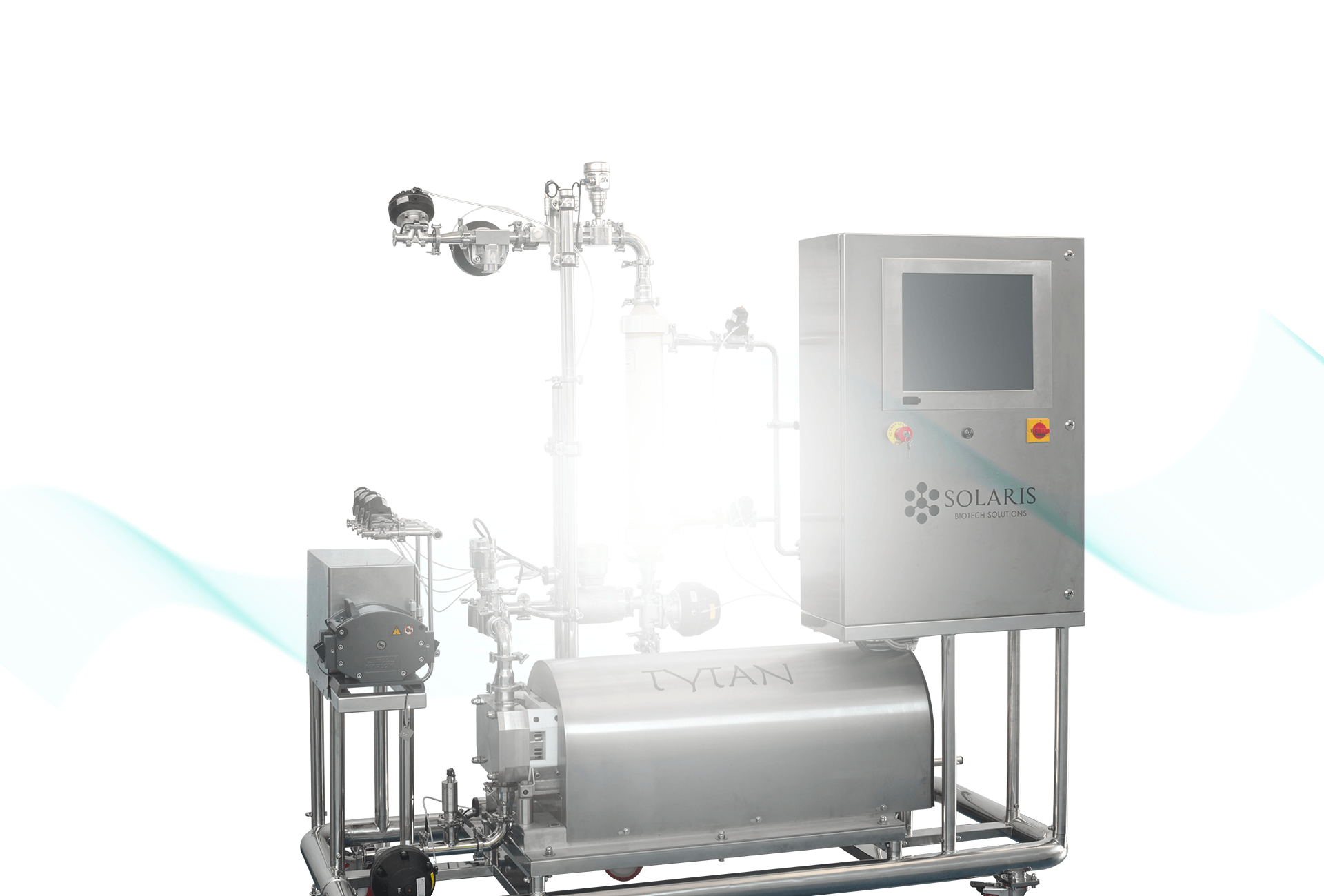

TFF TYTAN

more

Tangential flow filtration or Cross flow filtration Tytan develops a process in which unfiltered product (retentate) flows tangentially across a membrane surface. Any dissolved or undissolved permeate component smaller than the membrane passes through it, while larger suspended particulates remain in the retentate flow.

Features and benefits

Some features.

Turnkey

Starting from the clients’ URS, Solaris manufactures tailored TFF solutions, to be applied to the recovery and separation of biotechnological products in downstream operations.

Reliability

With TYTAN, customers can opt for custom-designed vessels with smart sensor technology integrated for optimal process workflow.

TFF Configuration Options

Based on specific process / product needs, TFF configuration can integrate several different membrane types including:

- spiral wound

- hollow fiber (polymeric)

- cassettes (polymeric)

- tubular (ceramic)

Donaldson Filtration Solutions

Filtration Membranes

Our filtration specialists are always ready to suggest the best membrane in terms of materials, geometrical configuration and operative parameters, in order to:

- concentrate at the best efficiency.

- avoid gel layer problem.

- optimize the cost/profit ratio.

- minimize scale up cost.

The Systems

The systems are fully suitable for inline CIP and compliant to the most current GMP regulations, and to PED standards.

The measurement and control system is based on a SCADA supervisory Lab View, SFC-10, connected to a PLC.

Software

- Innovative SCADA software LEONARDO 3.0: a smart and user-friendly controller designed to provide a high level of automated management of the fermentation/cultivation processes.

- Data extraction in .csv format.

- Remote access via PC, tablet or smartphone, with QR code scanning or dedicated portal.

- Remote control for after sale assistance.

- Synoptic page with manual operation and active monitoring of relevant process parameters

- Save, load or delete recipes

- Continuous trend graphs representation to track, print and export data on up to 6 processes and set point variables

- Attribution to the variables of maximum and minimum values to act as alarm thresholds