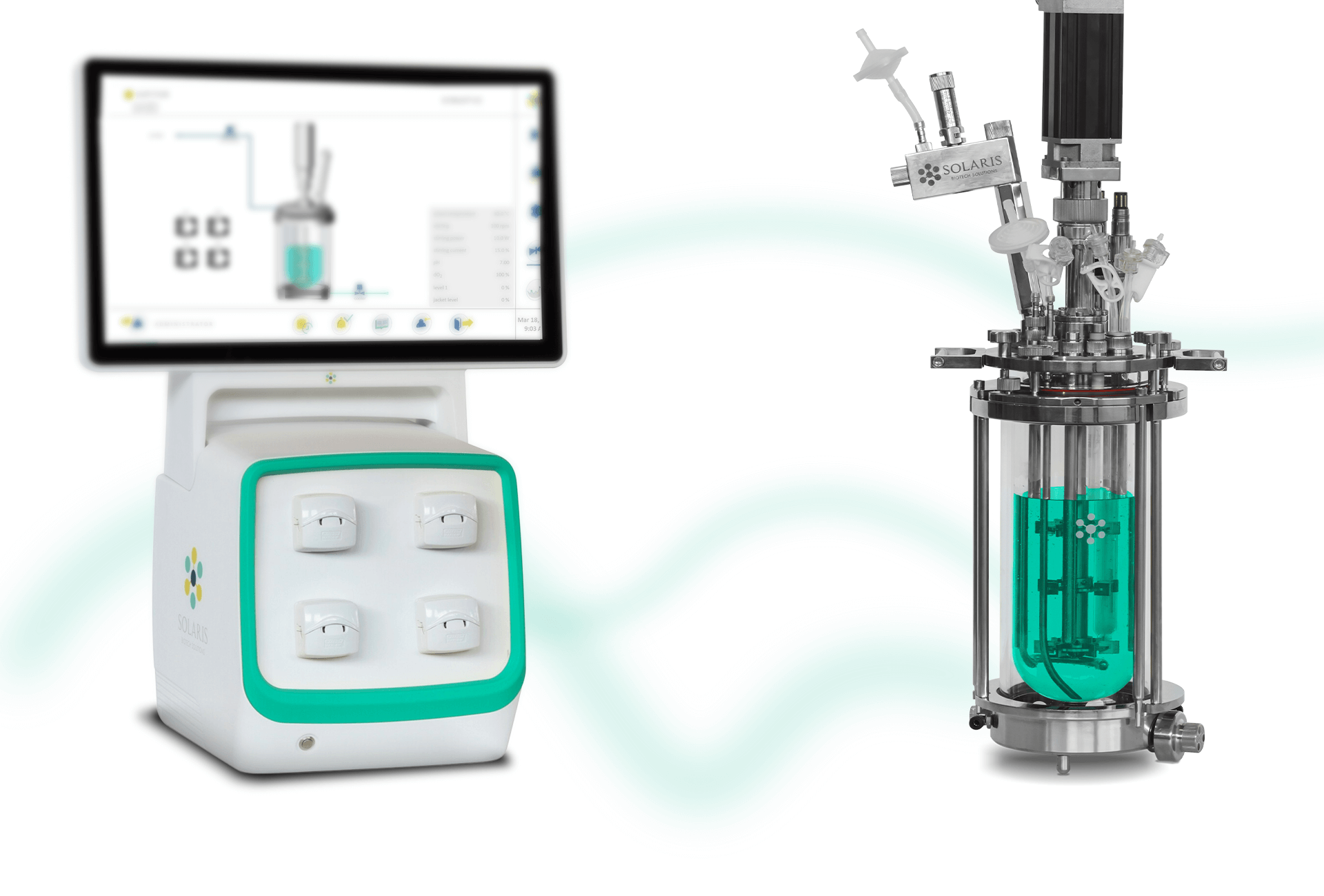

Single & parallel autoclavable stirred

mini-fermenter/bioreactor

Solaris Lab

JUPITER

more

The Jupiter platform offers multiple autoclavable vessel sizes and designs from 2.0 L up to 10.0 L total volume. The system is highly configurable, offering a wide range of measurement and control options. Pressure control up to 1.6 bar is also available in the 2 and 4 L volumes.

Solaris JUPITER

Features and benefits

Some features.

So Jupiter

Six Solaris

Lab Colors

The Pressure

The Jupiter Pressure, with the same configuration, control options and parametres as the standard one, gives the ability to run bioprocesses at higher pressure conditions.

The system is highly configurable, offering a wide range of measurement and control options.

- Pressure control up to 1.6 bar (with constant gas-in and gas-out flux) controlled from software

- Vessel dimensions available in 2 and 4 litres total volumes with jacketed design

- Suitable for batch, fed-batch anc continuous processes and parallel control up to 24 units

Why doing the Pressure version?

Why not!

Software

- Innovative SCADA software LEONARDO 3.0: a smart and user-friendly controller designed to provide a high level of automated management of the fermentation/cultivation processes.

- Full version included in the equipment supply.

- Up to 24 units managed in parallel with a unique HMI (24”).

- Data extraction in .csv format.

- Remote access via PC, tablet or smartphone, with QR code scanning or dedicated portal.

- Remote control for after sale assistance.

JUPITER can be

equipped with

Bioreactor

Accessories

Solaris Lab JUPITER Applications

Can be used for

In the following

application fields

Find your applicationDietary supplements, Food additives.

Antibiotics, Antitumorals, Human Vaccines, APIs, Hormones, Non-addictive Pain Killers, Monoclonal Antibodies.

Bioactive ingredients, Hyaluronic Acid, Q10 Coenzime.

Meat/cheese/wine starters, Meat Preservatives, Cellular Agriculture, Flavors, Plant-based substitutes for meat products, Low Carb Drinks, Fermented Drinks.

Biopolymers, Bioplastics.

Biofertilizers, Biopesticides, Algae Fertilizer.