Advantages of Tangential Flow Filtration

26/03/2021

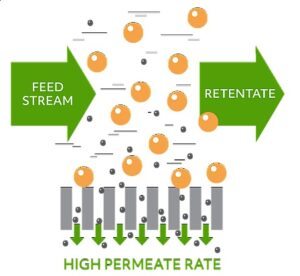

Tangential Flow Filtration, aka Cross Flow Filtration, is an important step in bioprocessing but has its unique set of challenges.

Unlike a dead-end impact filter where the product flows perpendicular to the filter (prone to clogging), the product stream in TFF moves in parallel to the filter. This allows solids to be kept in solution and minimizes the buildup of a “filter cake” which can foul the membrane.

Today’s industrial design — even in compact, benchtop TFF systems — provides for accurate and continuous transitions to scaling up.

Applications for TFF

- Separation of large and small biomolecules, clarification and/or removal of contaminants.

- Diafiltration for buffer exchange, desalination, and removal of biomolecules.

- Concentration and desalination of proteins, peptides, DNA/RNA, and oligonucleotide.

- Purification and/or recovery of recombinant proteins and antibodies from cell culture media.

- Purify and/or recover plasmid DNA from cell culture or cDNA from blood.

- Cell harvesting (bacteria, yeast, mammalian cells.)

- Fractionate mixtures of proteins/peptides.

- Clarify and desalt whole cell lysates and homogenized tissue.

- Sample prep for chromatography.

- Reduce Bioburden and/or clean up water, solutions, buffers, and media (remove and/or reduce endotoxin load.)

- Recover and or remove virus particles and/or vaccines.