Single and Parallel Standard

SIP Fermenter/Bioreactor

Solaris Lab

GENESIS

Learn

more

more

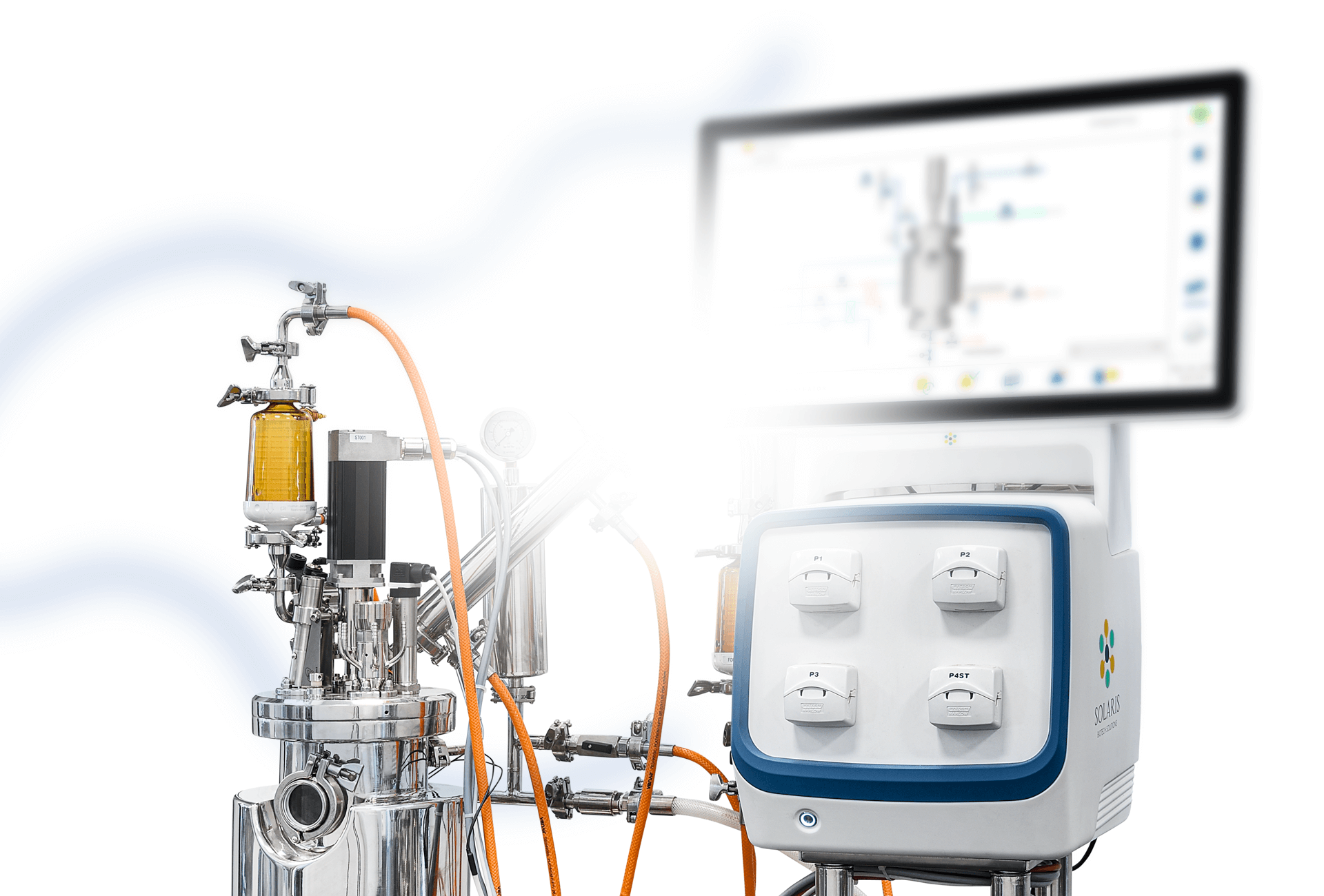

GENESIS is a compact benchtop SIP fermenter/bioreactor, available from 7.5 up to 20 L total volume.

Solaris GENESIS

Features and benefits

01

4 different volumes (7,5 L, 10 L, 15 L, 20L),, 2.5: 1 H/D ratio

02

AISI 316L vessel.

03

Sterilization with steam, electrical heaters or a combination of both.

04

Double jacket (side-bottom) for greater heat transfer efficiency and optimal temperature control.

05

Microbial (Toro sparger, Rushton impellers, baffles) and cell cultures (Sintered sparger, Marine impellers, baffles caps) configurations available.

06

Wide range of measurement and control options, including temperature, pH, dO 2 , dCO 2 , redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells).

07

Modbus digital sensors reduce background noise and guarantee quick response time.

08

Suitable for batch, fed-batch and continuous processes.

09

LEM01, the PLC-based control system supplied with the unit, integrates 4 fixed or variable speed peristaltic pumps.

10

Powerful and accurate (1 RPM) brushless motor.

11

Optional integration of up to 4 analog input/output connections, choosing between 0-10 V and 0-20 mA/4-20 mA (e.g. pumps or valves with power supply independent from Solaris electrical cabinet)

12

Different gas mixing strategies with up to 5 TMFC and/or solenoid valves.

13

SALAS (Solaris Sterile Liquid Addition System) included in the standard configuration.

14

The thermoregulation and aeration loops are external from the PCS, on a dedicated support with a combination of stainless-steel and flexible tubing.

15

Illuminated sight glass on the vessel lid, and circular sight glass on vessel side.

Some features.

Automatic sterilization with steam or electrical heaters.

Six Solaris

Lab Colors

Software

- Innovative SCADA software LEONARDO 3.0: a smart and user-friendly controller designed to provide a high level of automated management of the fermentation/cultivation processes.

- Full version included in the equipment supply.

- Up to 24 units managed in parallel with a unique HMI (24”).

- Data extraction in .csv format.

- Remote access via PC, tablet or smartphone, with QR code scanning or dedicated portal.

- Remote control for after sale assistance.

Genesis can be

equipped with

Bioreactor

Accessories

Solaris Lab GENESIS Applications

Can be used for

Basic research

Process development and optimization

Scale up and scale-down studies

Scale up and Small production

In the following

application fields

Find your applicationNutraceutical

Dietary supplements, Food additives.

Biotech and Pharma

Antibiotics, Antitumorals, Human Vaccines, APIs, Hormones, Non-addictive Pain Killers, Monoclonal Antibodies.

Cosmeceutical

Bioactive ingredients, Hyaluronic Acid, Q10 Coenzime.

Food & Beverage

Meat/cheese/wine starters, Meat Preservatives, Cellular Agriculture, Flavors, Plant-based substitutes for meat products, Low Carb Drinks, Fermented Drinks.

Biomaterials

Biopolymers, Bioplastics.

Agriculture

Biofertilizers, Biopesticides, Algae Fertilizer.